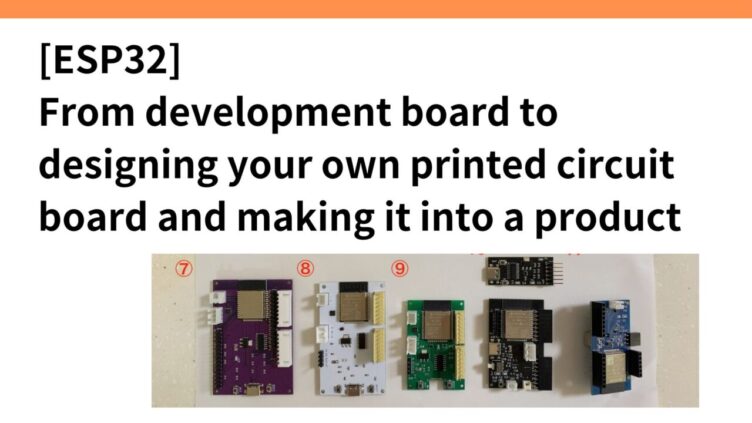

[ESP32] From development board to designing your own printed circuit board and making it into a product

The cat-shaped talking robot Mia is developed on a home-made board using an ESP32 Wi-Fi Bluetooth module; this memorandum summarises the process from the initial development using an ESP32 development board to the creation of a home-made board and several changes for the product.